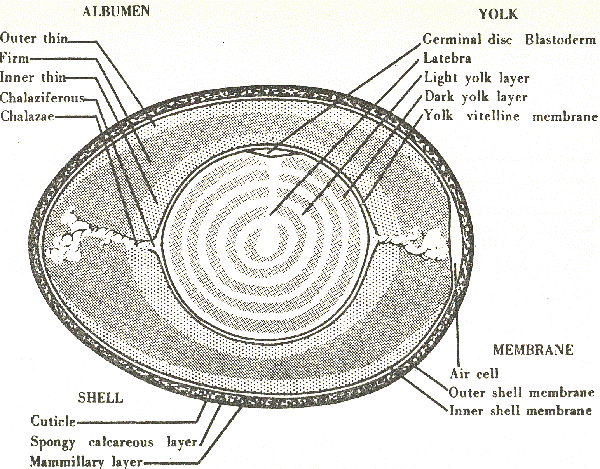

Structure of egg:

The egg is nature’s device to produce a chick. So, it has the necessary infrastructure for the production and nutritional requirements of developing embryos and newly hatched chicks.

There are four main components of a hen’s egg:

- Shell

- Shell membranes

- Albumen or white

- Yolk

The yolk develops in the functional left ovary of the hen as an ovum, largely during the final 10 days before release. After ovulation or release, a fully developed ovum or yolk is engulfed in the oviduct, where a gel of albumin or egg white is secreted to surround the yolk for a few hours. Finally, the shell membranes and the calcareous shell are deposited in the oviduct for nearly 16 hours before the egg is laid.

i. Shell: The outer protective covering of an egg is the shell, which comprises around 11% of its total weight. It is mainly composed of calcium carbonate. The shell contains numerous minute pores on the entire surface, which are partially sealed by keratin. These pores allow the loss of carbon dioxide and moisture from the eggs. However, a few of them (hardly 12-20) may permit bacterial penetration within the egg under specific circumstances (known as patent pores). The shell structure consists of three basic units:

a. Outer cuticle made up of keratin

b. Middle spongy or calcareous layer

c. Inner mammillary layer

ii. Shell membranes: The shell is attached to the shell membranes. The outer thick and inner thin membranes are usually inseparable except at the broader end of the egg forming an air cell. The shell membranes are a part of the in-built defense mechanism in the egg because of their role as an effective barrier against bacterial invasion. The air cell continues to increase in size during storage due to loss of moisture and shrinkage of egg contents.

iii. Albumen: The white or albumen portion of an egg constitutes about 58% of the total weight of an egg. It occurs in four layers as follows:

a. Outer thin layer

b. Outer thick layer

c. Inner thin layer

d. Inner thick white or chalaziferous layer

The proportion of thin and thick white varies according to the breed and age of the hen. Thick content is comparatively more. The inner thick white layer surrounds the vitelline membrane of the yolk and its firm mucin-like fibers continue as chalazae, which has the specific function of keeping the yolk in the center.

The pH of liquid whites ranges from 7.6 (fresh) to 9.3, depending on the amount of carbon dioxide lost from the egg. Liquid egg whites obtained from stored eggs usually have a higher pH; as the eggs are stored, the pH will increase due to carbon dioxide loss through the shell during storage. The amount of carbon dioxide loss is the only factor that can affect the pH of liquid egg whites, which depends on the egg temperature, the amount of carbon dioxide in the environment, and the degree of egg sealing or oiling.

iv. Yolk: The yolk constitutes nearly 31% of the total egg weight. It consists of the following four structures from the outside:

a. Vitelline membrane

b. Concentric rings of light and dark yolk material

c. Latebra (cone like portion extending to the center of yolk)

d. Germinal disc (located in the cone of latebra)

The pH of fresh and pure yolk is 6.0 and it increases to about 6.4-6.8 during storage.

Fig. Structure of an egg

Chemical Composition of egg:

An egg consists of 11% shell, 58% albumen and 31% yolk. The cuticle of egg shell is composed of a foaming layer of proteinaceous matter especially keratin and covers the calcified portion of the shell which is made up of calcium carbonate (94%) with minor quantities of calcium phosphate (1%), magnesium carbonate (1%) and proteinaceous material, especially keratin. The true cell membrane consists of protein fibers. The inner membrane is comparatively thick.

| Component | Total (%) | Water (%) | Protein (%) | Fat (%) | Ash (%) |

| Whole egg (including shell) | 100 | 65.5 | 11.8 | 11.0 | 11.7 |

| Albumen | 58 | 88.0 | 11.0 | 0.2 | 0.8 |

| Yolk | 31 | 48.0 | 17.5 | 32.5 | 2.0 |

| Calcium carbonate (%) | Calcium phosphate (%) | Magnesium phosphate (%) | Organic matter (%) | ||

| Shell | 11 | 94.0 | 1.0 | 1.0 | 4.0 |

| Species | Wt. of egg (g) | Proportional parts (%) | ||

| Albumen | Yolk | Shell | ||

| Chicken | 58 | 55.8 | 31.9 | 12.3 |

| Duck | 80 | 52.6 | 35.4 | 12.0 |

| Turkey | 85 | 55.9 | 32.3 | 11.8 |

| Goose | 200 | 52.5 | 35.1 | 12.4 |

| Guinea fowl | 40 | 52.3 | 35.1 | 12.6 |

| Ostrich | 1400 | 53.4 | 32.5 | 14.1 |

| *Quail | 8 | 53.7 | 32.2 | 14.1 |

EGG QUALITY

Quality has been defined as the inherent properties of any given food which determine its degree of excellence in terms of acceptance or rejection of the food by the consumer. Egg quality is a general term that refers to several standards which define both internal and external quality. External quality is focused on shell cleanliness, texture and shape, whereas internal quality refers to egg white (albumen) cleanliness and viscosity, size of the air cell, yolk shape and yolk strength.

MEASUREMENT OF EGG QUALITY

- Exterior egg quality: It includes those quality factors that are judged externally without breaking the eggs.

- Egg size: The size of an egg is expressed in terms of its weight. It varies among different species. Besides the species and the breed, the factors that are responsible for egg weight include age, body size, season, diet, health conditions, inbreeding etc. On the basis of weight, eggs are being graded into different grades.

- Egg shape: Shape of an egg plays an important role in the consumer appeal as well as in the packaging of eggs. Abnormally shaped eggs have more chances of breakage in the packaging material during transportation. Eggs are oval to elliptical in shape with one end broad and other end narrow. Any variation from this is considered as abnormal. The shape of eggs is determined by the shape index.

- Shell color: Shell color of domestic birds may be white or many shades of brown. The individual, seasonal and genetic variations are responsible for variation in shell color.

- Shell texture: There exists a variation in the texture of egg shell. Egg shells may be smooth, uneven, rough, showing presence of ridges, grooves etc. It could be due to uneven deposition of calcium in shell during shell formation. On the basis of shell texture, eggs are divided into 3 grades.

- Practically normal egg’s shellis having good even texture and strength and is free from rough areas or thin spots.

- Slightly abnormal is one whose shell may be somewhat slightly faulty in texture.

- Abnormal egg is that which shows pronounced ridges, thin spots of rough areas.

- Shell soundness: An egg shell should be sound enough for better hatchability. On the basis of shell soundness, eggs are divided into four grades viz. sound, check, leaker and smashed. Sound egg is one whose shell is unbroken without any cracks. Check is one whose shell is broken but the membrane is intact so that the contents do not exude. Leaker is that egg from which the egg contents are exuding due to broken shell and shell membrane. Smashed egg is that egg whose shell is either crushed or smashed.

- Shell cleanliness: The hatchability as well as the shelf life of clean eggs is better than soiled/dirty eggs. The effect of contamination in the form of litter, droppings, blood etc. is significantly reflected in their hatchability. On the basis of shell cleanliness, eggs are graded into clean, slightly stained, moderately stained and dirty eggs. Clean egg is that egg which is free from any foreign material, stains, discolorations that are readily visible. Any egg whose shell is free from adhered dirt but shows stains covering up to 1/16th of the shell surface is called slightly stained egg. Moderately stained egg is that whose shell surface is free from adhered dirt but has stains of moderate degree covering not more than 1/4th of the shell surface. Dirt egg is that in which the adhered dirt, moderate stains cover more than 1/4th of shell surface.

- Shell porosity: Pores are present in the egg shells for gaseous exchange for the purpose of respiration of developing embryo. Shell pores also allow escape of carbon dioxide and moisture besides allowing entry of microbes. Shell porosity can be measured by:

- Measuring the weight loss of eggs under standard conditions of temperature and humidity.

- Dye method: Dye the egg shell in a solution of methylene blue or crystal violet (3g/litre) and break the egg open. The number of pores penetrated by the dye is compared with graph of photographic standards. On the basis of this, score from 1 to 10 is given to each egg.

The different physical tests done to check the external quality of eggs are:-

- Shell thickness – can be measured by AMES thickness gauze at both the ends and middle and average is taken. ( chicken egg = 0.33 mm, quail egg = 0.13 mm, turkey egg = 0.4 mm and duck egg = 0.3 mm)

- Specific gravity – can be estimated by brine floatation technique. It ranges from 1.060 to 1.115 in units of 0.005.

- Percent shell – weight of the dried shell divided by weight of the egg multiplied by 100.

- Impact strength – it is determined by following the falling ball technique.

F = M (2 AH) ½

Where,

F = force in dynes

M = mass of egg (g)

A = acceleration due to gravity

H = height of fall (cm)

- Shape index = width in mm/ length in mm X 100

- Specific gravity = weight in gram / volume in cc

B) Internal egg quality: Internal quality factors of eggs include

- Size of air cell

- Albumen quality

- Yolk quality

Both subjective (candling, USDA/Van wagenan charts) as well as objective (albumen index, yolk index, Haugh unit) methods are employed.

- Candling: Candling means visual examination of eggs by holding the egg before a light in a darkened room in such a way that the interior of the egg is illuminated. Eggs can be sorted according to interior quality fairly accurately by an experienced candler. The quality characteristics which can be observed through candling include size of air cell, yolk shadow position, presence of blood/meat spots and presence or lack of germ development. Efficiency of candling depends upon the speed in carrying out the operation and accuracy of judgement in the interpretation of results. It is an age old conventional method of judging egg quality and is still most widely used. The chief advantage of this method is that it is quick yet non-destructive method of testing.

- USDA/Van Wagenan Charts: These two methods are based on same principle of comparing egg with standard pictures of broken out eggs. USDA charts contain 12 pictures of broken out eggs on 2 planes which can be compared with broken out eggs to assess their quality. The Van Wagenan chart also called as Cornell chart contains 9 pictures. In both the charts, good quality eggs when broken out on flat surfaces exhibit a thick white standing firm around the yolk and yolk standing up (high in better quality eggs and low in poor quality eggs). In low quality eggs, the white spreads out depending upon the degree of thinning.

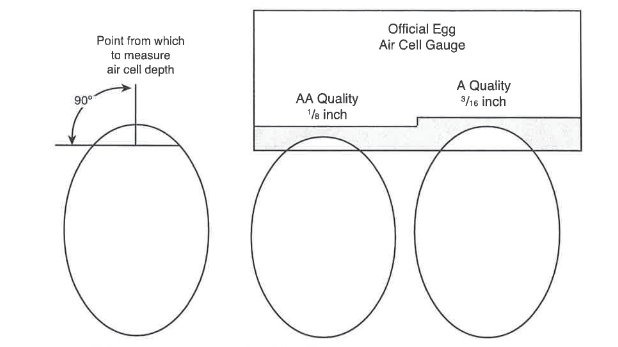

- Size of air cell: Air cell is the space present between the two shell membranes at the broader end of the egg. It is an important parameter to evaluate the quality of the egg. The size of the air cell depends upon the age of the egg, shell porosity, temperature and humidity of environment. Larger the size of the air cell, poorer is the quality of the egg. The size of the air cell can be judged by candling and measured by air cell gauge.

On the basis of air cell size, eggs can be graded into three grades viz. practically regular, free air cell and bubbly air cell.

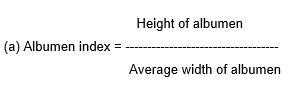

- Albumen quality: The internal quality of the egg is best judged by examining the quality of albumen as albumen is more sensitive to changes in temperature, humidity, age, breeding, feeding and diseases than yolk. The albumen quality can be measured by:

Albumen index of fresh egg should be 0.1 or above. Lower value indicates poor quality.

(b) Haugh Unit: It is an expression relating egg weight and height of thick albumen.

Haugh Unit = 100 log(H+7.57-1.7W0.37)

Where, H = Height of thick albumen (mm)

W = Weight of egg (g)

For fresh egg, Haugh units will be 105 and above

| Haugh Unit rating | Quality of eggs |

| 90 and above | Excellent |

| 80 – 89 | Very good |

| 70 – 79 | Acceptable |

| 65 – 69 | Fair |

| 60 – 64 | Consumer resistance point |

| 55 – 59 | Poor |

| 50 and below | Unacceptable |

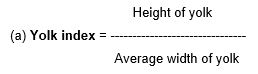

(v) Yolk quality: Factors which determine the quality of yolk include yolk index, yolk color and strength of vitelline membrane.

As the egg deteriorates, the vitelline membrane which holds the yolk in its position is ruptured and yolk flattens. In a good quality egg, the height of the yolk should not be less than 1/3rd of the width. Yolk index for fresh egg will be about 0.4.

Height of albumen/yolk is measured by tripod micrometer/spherometer and width by Vernier calliper

(b) Yolk color: It can be accomplished by comparing the broken out color of the yolk with Heiman-Carver yolk color rotor. This consists of 24 curved glass discs with concave surface painted with paint mixture in color from light yellow to deep orange red.

Yolk color can also be determined by using Roche color fan. It consists of 15 colored plastic tabs arranged as a fan corresponding to the color of egg yolk.

(c) Strength of vitelline membrane: Ability to withstand rupture of vitelline membrane during egg breaking operation denotes its strength.

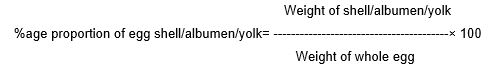

Additional parameter: The percentage of each egg component viz. shell, albumen and yolk can be estimated by applying the following formula.

| Grade | Wt. of egg (g) | Wt. of dozen eggs (g) | Shell | Air cell | White | Yolk |

| A extra large | 60 and above | 715 and above | Clean, unbroken and sound, shape normal | Up to 4mm in depth, practically regular or better | Clear, reasonably firm | Fairly well centered, practically free from defects, outline indistinct |

| A Large | 53-59 | 637-714 | ||||

| A Medium | 45-52 | 535-630 | ||||

| A Small | 38-44 | 456-534 | ||||

| B Extra large | 60 and above | 715 and above | Clean to moderately stained and sound, shape slightly abnormal | 8 mm in depth, may be free and slightly bubbly | Clear, may be slightly weak | May be slightly off centered, outline slightly visible |

| B Large | 53-59 | 637-714 | ||||

| B Medium | 45-52 | 535-630 | ||||

| B Small | 38-44 | 456-534 |

Eggs, which do not qualify under the above two grades, may be debarred for entering trade channels as fresh shell eggs.

| Size or Weight Class | Minimum net weight per dozen | Individual Egg weight |

| Jumbo | 30 ounces | 70 g |

| Extra Large | 27 ounces | 65-70 g |

| Large | 24 ounces | 56-65 g |

| Medium | 21 ounces | 49-56 g |

| Small | 18 ounces | 42-49 g |

| Peewee | 15 ounces | 35-42 g |

| Quality Factor | AA Quality | A Quality | B Quality | |

| Shell | Clean | Clean | Clean to slightly stained | |

| Unbroken | Unbroken | Unbroken | ||

| Practically normal | Practically normal | Abnormal | ||

| Air Cell | 1/8 inch or less in depth | 3/16 inch or less in depth | over 3/16 inch in depth | |

| Unlimited movement and free or bubbly | Unlimited movement and free or bubbly | Unlimited movement and free or bubbly | ||

| White | Clear | Clear | Weak and watery | |

| Firm | Reasonably firm | Small blood and meat spots present | ||

| Yolk | Outline slightly defined | Outline fairly well defined | Outline plainly visible, enlarged and flattened | |

| Practically free from defects | Practically free from defects | Clearly visible germ development but not blood | ||

| Other serious defects | ||||

| For eggs with dirty or broken shells, the standards of quality provide two additional qualities | ||||

| Dirty | Check | |||

| Unbroken, adhering dirt or foreign material, prominent stains, moderately stained areas in excess of B quality. | Broken or cracked shell, but membranes intact, not leaking. | |||

STEPS FOR MEASURING EXTERNAL QUALITY OF EGGS

Requirements: Eggs, distilled water, beakers, egg weighing balance, Vernier calliper

Steps:

- Remove the eggs from the packaging material and check for any visible abnormality on the shell surface. Any egg having a cracked shell is discarded.

- Take the weight of the eggs individually on a sensitive weighing balance.

- With the help of Vernier calliper, measure the width and length of the egg.

- Specific gravity: Take a beaker of 1000 ml capacity. Put 250 ml of distilled water into it. Now take the already weighed egg and slide it down into the beaker taking care not to beak it. Note the volume of distilled water displaced by the egg. Take the reading and calculate its specific gravity.

STEPS FOR MEASURING INTERNAL QUALITY OF EGGS

Requirements: Eggs, Vernier calliper, tripod micrometer, egg breaking table, petridishes, weighing balance, wiper, air cell gauge

Steps:

- Take an egg breaking stand having a flat glass surface (approximately 12 by 18 inches) or larger. The stand is set on a table of such height that the dial of the micrometer will be at eye level when in use.

- A knife is used to break the egg and carefully put the internal contents on the glass surface of egg breaking stand.

- Check for any visible abnormality of albumen and yolk.

- With the help of a Vernier calliper, measure the diameter of both the albumen and yolk and with the help of tripod micrometer, measure their height (take the average of at least 2 readings).

- Carefully take the yolk into an already weighed petriplate and weight it on a sensitive weighing balance.

- With the help of a wiper, move the albumen part from the glass surface to a suitable container/petriplate and record its weight. If possible, weigh thick and thin albumen separately.

- Take the weight of shell separately.

- The depth of the air cell is measured by air cell gauge at the point of greatest distance between the top of the cell and an imaginary plane passing through the egg at the lower edge of the air cell where it touches the shell.

- Put the values in suitable formulae and calculate the results and accordingly give your interpretations.

Precautions to be taken:

- The eggs must be cooled to an internal temperature between 45 and 60°F (7.2 and 15.6°C). The internal temperatures of the eggs selected for the breakout must be uniform to provide accurate and consistent results.

- Care must be taken in using the breaking knife so the thick albumen is not ruptured. Blunt edges, such as a table edge, may cause the shell to splinter, with the possibility of puncturing the thick albumen.

- The egg should be held as near the glass as possible and the contents emptied very gently from the shell.

- Haugh units should not be measured or recorded when the thick albumen or yolk membrane has ruptured.

- The surface on which the egg contents are placed must be level.

- One egg at a time should be broken since it is important to measure the albumen height immediately after breaking. A delay of a few minutes can make a significant difference in the Haugh unit reading.

- If a micrometer is used for measuring Haugh units, it must be checked before using. Set it on the glass and turn the measuring rod down until it touches the surface of the glass on which the broken-out egg will be placed. To be sure that the rod is actually touching the surface of the glass, push the edge of a thin sheet of paper against the intersection of the rod and the glass. The procedure should be repeated from time to time during the breaking operation to be sure that the micrometer is properly adjusted.

- When determining albumen quality with a Haugh meter or micrometer, select a flat area in the surface of the widest expanse of the thick albumen for measurement. Eggs with very high albumen will not have a flat surface and in such cases a point about halfway between the yolk and the edge of the widest expanse of thick albumen should be selected. Care should be taken to avoid measuring areas over an air bubble or chalazae.

- The measuring rod of the micrometer should be rolled down slowly till it just touches the surface of the albumen. It should be raised and cleaned before placing it over the next egg to be measured.

Fig. Measuring air cell

EGG DEFECTS

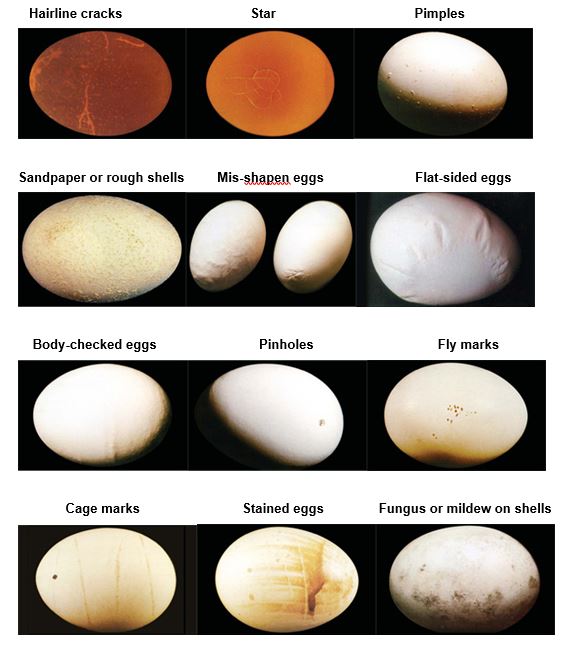

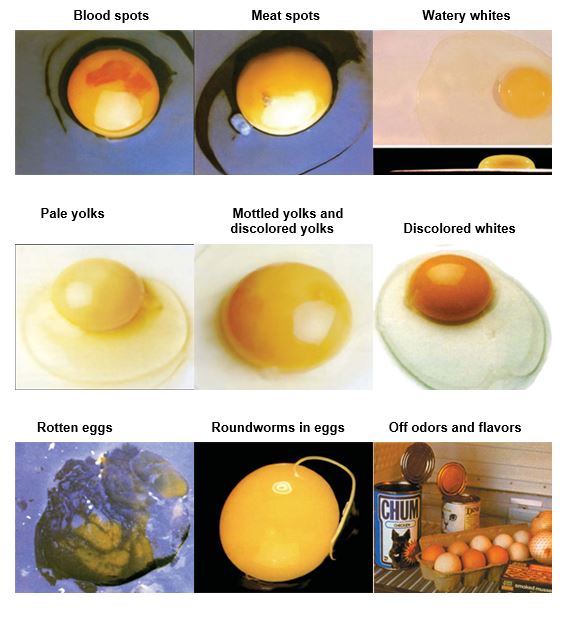

Egg defects are discussed in two groups: shell defects and internal defects.

A) SHELL DEFECTS

B) INTERNAL DEFECTS

Some common definitions:

Air cell – The air space between the inner and outer shell membranes, usually found at the broader end of the egg.

Albumen – The white of the egg.

Chalazae – White, twisted, rope-like structures attached to the thick albumen which anchor the yolk in the centre of the egg.

Cuticle – The outer membrane covering the egg shell which gives the shell a bloom.

Follicle – A sac-like structure in the ovary containing a developing ovum.

Germinal disc – A small, circular, white patch on the upper surface of the yolk, containing cells from which the chick develops if the egg is fertilised.

Grading – The process of classifying eggs by quality and by weight.

Ovary – The female reproductive organ in which the ova (yolks) develop. Only the left ovary is functional in hens.

Infundibulum – A funnel-shaped section of the oviduct, about 6 to 8 cm long, which collects the ovum as it is released from the ovary.

Magnum – Part of the oviduct, immediately after the infundibulum. It is about 30 cm long and secretes about 40% of the egg’s albumen.

Isthmus – A section of the oviduct about 12 cm long which secretes the shell membrane and some albumen.

Oviduct – A long, tubular organ which adds the egg white, shell membranes and shell to the yolk as it passes through.

Ovulation – The release of a mature ovum from an ovarian follicle. Ovum (plural ova) – An egg at the stage when it is a yolk without any white (albumen).

Shell calcification – The process of shell formation during the period the egg is in the shell gland (uterus). Shell membranes – Inner and outer membranes that together line the inside of the shell and adhere very closely to it.

Vitelline membrane – A thin, transparent membrane which surrounds and contains the yolk.

1 thought on “EVALUATION OF EXTERNAL AND INTERNAL QUALITY OF EGG”