PRESERVATION OF MEAT AND MEAT PRODUCTS

Meat preservation is the application of measures to delay or prevent certain changes which make meat unsuitable as a food or which downgrade some quality aspect of meat or its products.

It is done to:

- To delay product spoilage

- To extend shelf life of the products

- To improve product quality (texture, flavor etc.)

- To have some economic gain (reduction of labor cost, increased utilization etc.)

Preservation Techniques:

- COLD TREATMENT

- THERMAL TREATMENT

- DEHYDRATION

- FERMENTATION

- SMOKING

- CURING

- IRRADIATION

- CANNING

1. COLD TREATMENT

a. Chilling

A process of prolongation of shelf life of meat by lowering the temperature of the meat products to a point above the freezing temperature.

Refrigeration: The ‘refrigeration’ means storage at a temperature between 2 to 5°C. Refrigerants are liquid or liquefied gases with low boiling points eg: ammonia or hydrofluoro-carbons etc. used for refrigeration process.

b. Freezing

A method of long time storage of meat below the freezing point of the product to be preserved.

- Works by completely stopping enzyme activity and inhibiting spoilage microorganisms (Bacteria, Yeasts, Molds)

- Starts at -1.5°C

- Decreases water activity (aw) drastically

- 50% water freezes at -2.5°C, 75% at -7°C

- Tight-fitting, moisture proof packaging and steady storage temperature (-18 °C to -20 °C or even -30 °C) are most critical requirements

- Prolonged storage life of 6-12 months

- Gradual decrease in odor, flavor and acceptability of processed products

Freezing rates in different methods:

- Slow freezing = 0.2cm/hr

- Quick freezing = 0.53cm/hr

- Rapid freezing = 5-10cm/hr

- Ultra rapid freezing/cryogenic = 10-100 cm/hr

Care for freezing of processed meat products:

- The processed meat products must be of good microbiological and chemical quality

- GMP must be followed before pre freezing

- Refrigeration or protection from contaminants in case of delay

- Freezing as soon as possible in post processing condition

- Must be in accordance with predetermined parameters

- Storage usually -10°C to -30°C (usually at -18°C) in well packaged condition

Dehydrofreezing:

Dehydrofreezing is a method of food preservation that combines the techniques of drying and freezing (Dehydrofreezing is not technique of freeze-drying, freeze drying is a method that forms a vacuum while the food is freezing). However, 70 percent of the moisture is removed from the food products and then stored in the freezer, the final product achieve a better taste.

- In dehydrofreezing, the foods are partially dried and then frozen.

- Moreover, since they have been dried, they take less space. In addition, the taste and color of such foods is definitely better than foods that have only been dried. Another great advantage of dehydrofrozen foods is that they reconstitute in about one-half the time it takes for dried foods, making the former a quicker and easier option.

Freeze drying:

- The process where moisture is removed from the product using a very low temperature and a vacuum.

- Only about 3-4% moisture remains in the product at the time of packaging.

- The end product weight is reduced by over 90%, while the volume stays the same.

- This remarkable process concentrates the fresh taste, natural color, and texture of meat in its freeze dried state.

- When re-hydrated with water, the product will maintain the texture and shape of fresh meat, with no shrinking.

- Freeze Dried Meat Combo will store for 10 to 15 years in sealed air tight cans (oxygen absorbers included) under ideal storage conditions (cool, dry place).

2. Thermal Treatment

Thermal processing as a method of preservation is used to kill spoilage and potentially toxic microorganisms in meat and meat products and to inactivate endogenous enzymes that could cause deteriorative changes. Two general levels of heat processing are usually employed in meat preservation. A moderate heating process where products reach temperatures of 58-750C is employed in the cooking of most processed meat items. Severe heating generally to temperatures above 1000C is used to prepare commercially sterile meat products that are stable at room temperatures for one or more years. This process is known as sterilization.

Basic concepts that determine heat treatment requirements:

- TDT (Thermal Death Time): It is the time required to destroy given no. of organisms at constant specified temperature.

- D-Value (Decimal Reduction Value): It is the time usually expressed in minutes at a given temperature to kill 90 % of microorganisms that are present in the food.

- Z-Value: It refers to o C or 0 F by which the temperature must be raised in order to obtain ten-fold increase in the death rate of the microorganisms.

- F-Value: It is the equivalent time in minutes at1210 C of all heat applied to the product with respect to its capacity to destroy spores or vegetative cells of a particular organism.

- 12-D Concept: It refers to process lethality requirement. It implies the minimum heat process required to reduce the probability of survival most resistant Clostridium botulinum to 10-12. This concept is effectively used in canning industry.

Adverse changes induced by heat:

- Protein denaturation which results in shrinkage and loss of fluid

- Accelerates oxidative rancidity

- Responsible for the formation of Maillard reaction by-products that are responsible for burnt flavor

- Warmed over flavor (WOF) generally occurs when cooked products are reheated. This is attributed to disruption of membranes and subsequent exposure of phospholipids to oxygen.

3. DEHYDRATION

The drying of meat in the sun or over a fire dates back to prehistoric times. The preservative effects of dehydration are due to reduction of water activity (aw) to such a low level that microbial growth is inhibited and these meat products are stable without refrigeration.

Dehydration methods:

i) Hot air drying: Dehydration done in hot air dryers. It is most satisfactory for cooked ground meat. Factors such as particle size, temperature, and velocity of airflow must be carefully controlled. The residual moisture content of meat products dehydrated by this method is about 5%. Hot air drying is a slow process that is not applicable to uncooked meat or to large pieces of cooked meat because of surface hardening. Meat products dried by hot air also shrivel considerably and have poor rehydration properties due to protein denaturation that occurs during the drying operation.

ii) Freeze drying (already discussed)

4. FERMENTATION

Meat fermentation is a low energy, biological acidulation (microorganisms work by converting sugars into acids), preservation method which results in unique and distinctive meat properties such as flavor and palatability, color, microbiological safety, tenderness, and a host of other desirable attributes of this specialized meat item.

Benefits of fermentation:

- Helps to preserve the food

- Extends shelf-life considerably over that of the raw materials from which they are made

- Improves aroma and flavor characteristics

- Increases its vitamin content or its digestibility compared to the raw materials

- Improves its proteolytic and lipolytic activities

- Inhibits undesirable organisms

- Example: “Pepperoni”

Lactic Acid Bacteria

This group is comprised of 11 genera of gram-positive bacteria (Carnobacterium, Oenococcus, Enterococcus, Pediococcus, Lactococcus, Streptococcus, Lactobacillus, Vagococcus, Lactosphaera, Weissells and Lecconostoc) which are used for the production of fermented meat products:

- Those that produce lactic acid as the major or sole product of glucose fermentation are designated as homofermentative.

- Those that produce equal amounts of lactic acid, ethanol and CO2 are termed heterofermentative.

- The lactic acid bacteria are mesophiles. They generally grow over a temperature range of about 10 to 40oC, an optimum between 25 and 35oC. Some can grow below 5 and as high as 45oC. Most can grow in the pH range from 4 to 8, though some at pH as low as 3.2 and as high as 9.6.

- Traditionally, the fermenting organisms come from the natural microflora or a portion of the previous fermentation and the source is called starter culture.

5. SMOKING

Treatment of meat and meat products with the smoke generated through the thermal destruction of the wood components like lignin and cellulose. The thermal destruction sets free more than 1000 desirable or undesirable firm, liquid or gaseous components of wood.

Following are the desirable effects of smoke compounds on meat products:

- Meat preservation through aldehydes, phenols and acids (anti-microbial effects)

- Antioxidant impact through phenols and aldehydes (retarding fat oxidation)

- Smoke flavor through phenols, carbonyls and others (smoking taste)

- Smoke color formation through carbonyls and aldehydes (attractive color)

- Surface hardening of sausages/casings through aldehydes (in particular for more rigid structure of the casing)

Depending on the product, smoke is applied at different temperatures; there are two principal smoking techniques (Cold smoking and Hot smoking). The principle of both methods is that the smoke infiltrates into the outside layers of the product in order to develop flavor, color and a certain preservation effect.

Cold Smoking:

The optimal temperature in cold smoking is 15 to 18°C (up to 26°C). Sawdust should be burned slowly with light smoke only and the meat hung not too close to the source of the smoke. Cold smoking is a long process which may take several days. It is not applied continuously, but in intervals of a few hours per day.

Hot Smoking:

Hot smoking is carried out at temperatures of 60 to 80°C. The thermal destruction of the wood used for the smoking is normally not sufficient to produce these temperatures in the smoking chamber. Hence, additional heat has to be applied in the smoking chamber. The relatively high temperatures in hot smoking assure a rapid color and flavor development. The treatment period is kept relatively short in order to avoid excessive impact of the smoke (too strong smoke color and flavor). Hot smoking periods vary from not much longer than 10 minutes for sausages with a thin calibre such as frankfurters but up to one hour for sausages with a thick calibre such as bologna and ham sausage and products like bacon and cooked hams

6. CURING

Addition of salt, nitrate, sugar, or in some instances, other ingredients for the purpose of preserving and flavoring of meat and its products is known as curing of meat. Curing is the oldest method of preservation of meat. Initially only salt was used but today variety of curing ingredients are used in meat industry, e.g. salt, sugar, nitrite, etc.

Curing Ingredients

i) Salt: The use of salt as a preservative is because at high concentrations salt exerts drying effect on both food as well as microorganisms. Moreover, it also slows down the action of proteolytic enzymes. Use of salt alone, however gives a salty, dry and harsh product, i.e. not very palatable. Also when used alone, it results in dark undesirably colored lean, product which is unattractive and objectionable. So generally, it is used in combination with sugars and nitrite and/or nitrates. Many of the bacteria are inhibited by salt concentration as low as 2%. However, halophilic organisms, which can grow in high salt concentrations, are also rapidly killed when exposed to salt concentrations of more than 10%. However, acceptability of the products is decreased when salt concentration in the product exceeds 2%. Recently emphasis has been placed on reducing the levels of salt in meat products in view of its relationship to hypertension.

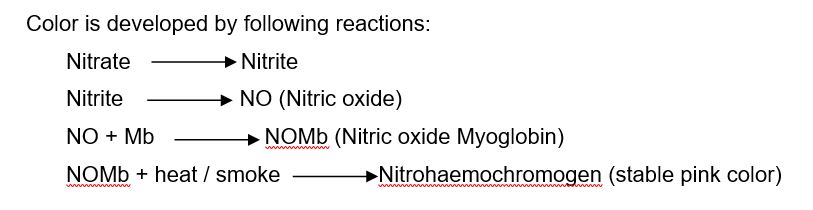

ii) Sodium nitrate/nitrite: The function of nitrite in meat curing is as follows:

- To stabilize the color of the meat.

- To contribute to the characteristic flavor of cured meat products.

- To retard the development of rancidity.

- To inhibit the growth of a number of food poisoning and spoilage microorganisms.

Nitrohaemochromogen (stable pink color) is very effective in preventing the growth of Cl botulinum. The antibotulinal activity is due to its inhibition of non-heme-iron-sulfur enzymes. It is effective only in combination with heat. Heating meat with nitrite produces Perigo factor, which is actually inhibitory to Cl botulinum.

Nitrites react with fatty acids to produce benzonitrite and phenylacetonitrite, which retard rancidity. However, nitrate / nitrites are also responsible for producing nitrosamines in meat because of interaction of nitrite with secondary amines during curing and / or cooking. These nitrosamines are carcinogenic and are present in small amounts in nearly all cured meat products, e.g. N-nitrosopyrrolidine. Permissible levels of nitrate and nitrite in meat products are 500 ppm and 200 ppm respectively.

iii) Sugars: The addition of sugars to cure is primarily for flavor. Sugar softens the products by counteracting the harsh hardening effects of salt by preventing some of the moisture removal and by direct moderating action on flavor.

iv) Phosphates: These are added to increase water binding capacity and thereby the yield of the finished product. The action of phosphates in improving water retention is in two folds:

- It raises the pH.

- It causes unfolding of muscle proteins, thereby making more sites available for water binding. Only alkaline phosphate is effective for water binding since acid phosphates may decrease pH and cause greater shrinkage.

Phosphates can chelate trace metal ions, hence retard development of rancidity in meat products.

v) Sodium Ascorbate and Erythorbate: Ascorbate and Erythorbate are isomers but Erythorbate is more stable than Ascorbate. Main functions are:

- Helps in reduction of metmyoglobin to myoglobin, hence it accelerates the rate of curing.

- Reacts with nitrites to increase the yield to nitric oxide.

- Act as antioxidant and stabilizes color and flavor.

- Under certain conditions, it reduces nitrosamine formation.

vi) Potassium Sorbate: Potassium sorbate is antimicrobial and is widely used as food preservative. It is very effective in inhibiting mold growth. It is also potent inhibitor of Clostridium botulinum particularly when used in combination with nitrites (Allergenic reaction may occur).

vii) Monosodium Glutamate (MSG): It is flavor enhancer and is used in number of products. It widens the taste buds and thus sensitivity of buds.

viii) Sodium and Potassium lactate: They prevent spoilage and extend storage life. Sodium lactate is better than potassium lactate because of the bitter taste of the later.

ix) Hydrolyzed Vegetable Proteins: It improves flavor and effectively increases the protein content.

Curing Methods

i) Dry curing: Dry ingredients are directly stuffed to the meat. It is mostly used for fatty acids. Curing ingredients draw enough moisture from the meat to form brine, which serves to transport ingredients into meat by diffusion.

ii) Pickle curing: In this method, ingredients are dissolved in water. The meat cuts are then submerged / immersed in the water until cure completely penetrates meat.

iii) Injection curing: Concentrated solution of ingredients is pumped into meat through artery or injected by needles into meat cuts.

iv) Direct addition method: In this method, curing agents are directly added to comminuted meat.

7. IRRADIATION

Radiation is a method of food preservation, which may be defined as the emission, and propagation of energy through space or through a material medium. The type of radiation of primary interest in food preservative is electromagnetic. The various radiations are separated based on their wavelengths, with the shorter wavelengths being the most damaging to microorganisms. The electromagnetic spectrum may be further divided as follows with regard to their utility in food preservation: microwaves, ultraviolet rays, X rays and gamma rays. The radiations of primary interest in food preservation are ionizing radiation. Ionizing radiations may be defined as those radiations that have wavelengths of 2000 A0 or less – for example alpha particles, beta rays, gamma rays, X rays and cosmic rays. Since they destroy microorganisms without appreciably raising temperature, the process is termed ‘cold sterilization’.

Characteristics of radiations in food preservation:

- Ultraviolet rays: UV light is a powerful bactericidal agent, with the most effective wavelength being 2600 A0. It is non-ionizing, is absorbed by proteins and nucleic acids resulting in photochemical changes that may lead to cell death. The mechanism of action is mutation of cell. It has poor penetrative power. So UV rays are used for surface application of foods.

- Beta rays: These may be defined as a stream of electrons emitted from radioactive substances. Cathode rays are same, but are emitted from the cathode of an evacuated tube. These rays possess poor penetration power. The commercial sources of cathode rays are van de Graaf generators and linear accelerators.

- Gamma rays: These are electromagnetic radiations emitted from the excited nucleus of elements such as 60Co and 137Cs. These are the cheapest form of radiations, since the source of elements are either byproducts of atomic fission or atomic waste products. They have excellent penetration power. 60Co has a half-life of 5 years, while that of 137Cs is 30 years.

- X rays: These rays are produced by the bombardment of heavy metal targets with high velocity electrons (cathode rays) within an evacuated tube. They are essentially same as gamma rays in other aspects. They have greater power to penetrate but very expensive, so these are not industrially applied.

- Microwaves: Microwaves lie between the infrared and radio frequency portion of the electromagnetic spectrum. This is a non-ionizing radiation. Each asymmetric molecule of food attempts to align itself with the rapidly changing alternating current field. As the molecules oscillate about their axes while attempting to go to the proper positive and negative poles, intermolecular friction is created and manifested as a heating effect. This is microwave energy. Microwave ovens with two frequencies, i.e. 915 and 2450 MHz. The most common use of microwaves is in destruction of molds in bread, pasteurization of beer, sterilization of wine, etc.

Irradiation is also referred as cold sterilization, since it destroys microorganisms without appreciably raising the temperature. Although the term ‘irradiation preservation’ generally refers to the use of ionizing radiations but non ionizing radiation, i.e. UV, infrared and microwaves are also lethal to microorganisms and may be used for meat preservation. The basic unit of radiation is the rad defined as being equivalent to absorption of 100 ergs/g of matter. Another unit is Gray (Gy).

1 KGy = 100 Krad

Gram +ve bacteria are more resistant to irradiation than Gram –ve bacteria, which are most sensitive to irradiation such as Pseudomonas and Flavobacterium. Yeast and mold are more resistant than Gram +ve bacteria while viruses are highly irradiation resistant but parasites are very sensitive to irradiation. Irradiation resistance of microorganisms is greater in the absence of oxygen. Irradiation resistance increases at colder temperature and decreases at higher temperatures. Irradiation resistance of bacteria is highest in lag phase.

Antimicrobial effect of radiation is attributed to the fragmentation of DNA of microorganisms and ionization of inherent water in the microorganism. Gamma radiations are the most widely used in food preservation, as they do not have much adverse effect on the food in desired doses. Among non-ionizing, UV rays are commonly used but for surface sterilization of the meat.

8. CANNING

Canning can be defined as preservation of foods in a sealed container. The major reason for canning meat is to provide safe product that have desirable flavor, texture and appearance.

Preservation of meat by thermal processing dated from the beginning of the 18th century when Appert (1810), whilst not aware of the nature of the process involved, found that food would remain edible if it was heated in a sealed container. This method of preservation has developed into the canning industry. During canning operation, Meat and meat products may be subjected to heat at two levels. Pasteurization (internal product temperature 150 0F, needs refrigeration storage) which is designed to stop microbial growth with minimum damage, and sterilization (internal product temperature 225 0F to 250 0F, can be stored at room temperature) in which all or most bacteria are killed but which alters the meat to considerable great extent. To destroy the spores of certain thermophiles would require a degree of heating which won’t greatly lower the organoleptic attributes of the commodity. In canning practice, commercial sterility is achieved by giving a degree of heat treatment sufficient to kill non-sporing bacteria and all spores that might germinate and grow during storage without refrigeration.

Can material: To prevent interaction between a meat product and the metal, cans are generally coated on the inside with an organic material, which is either acid resistant or sulphur resistant. Coatings and lacquers are complex blend of resins e.g. oleo-, vinyl-, epoxy, epoxyphenolic resins. Acid resistant coated cans are used primarily for fruits, which sulphur resistant for meat products as during the retorting operation, sulphur released from meat proteins will stain tinplate an unsightly black.

Canning Process: Single most-important phase of sterile canning operation is retorting. The retort operation serves two purposes

- Product are subjected to a high temperature for sufficient duration to destroy all organisms that might adversely affect consumer health as well as, other more resistant organisms that could cause spoilage under normal conditions.

- Products are cooked so they can be eaten directly as they come from the can.

The vessel used for heat treatment is known as retort.A retort is a steel tank in which metal crates or baskets containing the cans are placed for cooking and subsequent cooling.

To establish a retort schedule for sterile canned meat product, it is necessary to determine the rate of heat penetration at the slowest heating point in the can i.e. geometric centre of the product. This is calculated in terms of the destruction effect on Clostridium botulinum of an equivalent number of minutes at 250 0F. As a general rule, the one basic criterion is that all canned foods having pH 4.5 or above must be given a minimum safe cook sometimes referred to as botulinum cook.

Conventional canning is done in following steps:

- Preparation of meat and gravy: Carcass is deboned and 4 cm meat chunks are prepared. Meat gravy is prepared using condiments, tomatoes, dry spices and salt etc.

- Precooking: meat and gravy are pre-cooked at 700C for 15 minutes. It results in shrinkage of meat chunks and lowers initial microbial count.

- Filling: Filling in cans may be done manually or mechanically leaving proper head space. Half of the gravy is filled first followed by meat chunks and finally the rest of gravy. Special care is taken to avoid trapping of air during the operation.

- Exhausting: it refers to removal of air from the container before it is closed. It is necessary to minimize strain on the can seams due to expansion of air during heat processing.

- Seaming: this is usually doe by double seamer machine.

- Retorting or thermal processing: the product is subjected to high temperature under pressure for sufficient duration to achieve commercial sterility

- Cooling: retorting is followed by very fast cooling up to 30-400C to give shock to thermophilic bacteria.

- Storage: cans should be stored in a cool and dry place preferably at a temperature of about 200C

Aseptic canning:

A method of sterilizing container and product separately and then assembling them in an aseptic atmosphere to achieve a sterile package that can be stored at room temperature. The product to be canned is heated while flowing continuously to a temperature around 300 0F. At this temperature, sterility is achieved in a very short time.

Flash 18 Process:

The principal characteristics of the flash 18 process are filling of cans in a pressurized room under 18 lb air pressures at temperature of 225 0F and holding them at this temperature for a sufficient time to achieve sterilization. The cans are closed under the same conditions, thus eliminating retorting.

12 D concept:

Used in canning industry it implies the thermal process required to reduce the population of most resistant spores of Cl. Botulinum by (1012times) (Generally is 2.52 mln. at 250 0F). As Cl. Botulinum spores cannot germinate at pH below 4.6 this process is only necessary for food above this pH.

Common defects in cans due to under processing:

- Flipper: One end becomes convex by striking or heating due to gas production.

- Springer: Can has both ends buldged. If one end is pushed, the other pops up due to gas production.

- Soft swell: Can has both ends buldged but may be dented by pressing.

- Hard swell: Cannot be dented by hands. These are often hydrogen swells by action of acid on iron, other gases that may accumulate are H2S and CO2.

Common canned meat spoilage bacteria:

| Types of Organism | Appearance of can | Appearance of product |

| Flat sour B. sterothermophilus B. coagulans | Flat | Sour, abnormal odor, sometimes cloudy liquor |

| Cl. thermosaccharolyticum | Can swell, may burst | Fermented, sour, cheesy, butyric odor |

| Cl. nigrifaciens | Can flat, H2S gas absorbed by product | Usually blackened, rotten egg odor |

| Cl. putrifaciens Cl. sporogenes, | Can swell, may burst | Partially digested, pH little above normal putrid odor |

| B. subtilis B. mesentricus | Can flattened, usually no swelling except in cured meat where NO3 and sugar present. | Coagulated evaporated milk, black beets |

1 thought on “PRESERVATION OF MEAT AND MEAT PRODUCTS”